In addition to the use of antibacterial deodorant and fertilizer for plants, a few people know that coffee grounds are also a great source of raw materials for making environmentally friendly coffee bioplastics.

The idea comes from environmental responsibility and the desire to find a new direction for coffee grounds

According to the World Economic Forum (WEF), it is estimated that more than 2 billion cups of coffee are consumed globally every day and accordingly 6 million tons of coffee grounds are discharged into the environment every year. A small amount is used as fertilizer, but most of the residue is usually wasted and then gradually buried in the ground. If coffee grounds are not treated with the right waste treatment method, it will decompose and release methane, a gas that makes the Earth 86 times warmer than CO2.

Coffee grounds are a seemingly innocuous thing, but have unpredictable consequences later on.

Stemming from environmental responsibility and the desire to find a new direction for coffee grounds, during nearly 10 years of research, the Biopolymer brand has launched a prominent coffee bioplastic product to the market with raw materials. This product is made of 60% coffee grounds, ensuring to meet the most stringent standards of quality and safety inspection.

What is coffee bioplastic?

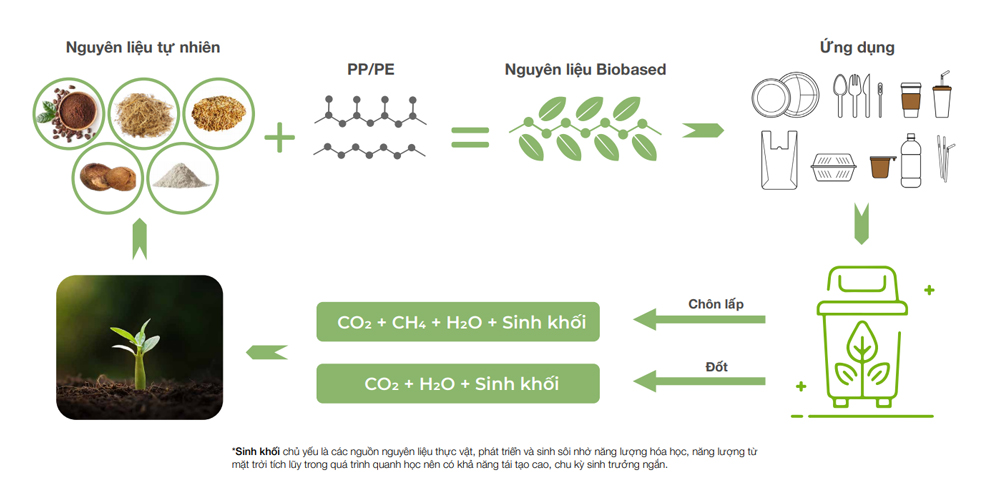

Bioplastic made from coffee is a unique combination of natural coffee grounds and traditional PP/PE, so it is capable of degrading into water, CO2 and biomass without causing environmental pollution and safe for human health.

Especially with natural coffee ingredients up to 60%, so the biodegradability is optimizedWith superior quality and high biodegradability, coffee bioplastic which is researched by a team of experienced engineers for more than 10 years is confident to be the most unique and optimal source of materials. This material also has the ability to completely replace traditional PP/PE, promising to bring a new transformation to Vietnam’s plastic industry. bringing the most positive impact to the environment.

What’s unique about coffee bioplastic?

1. Derived from special coffee grounds

Coffee grounds – a seemingly ordinary material, is now used to become the main ingredient of coffee bioplastic products. Not only keeping the features of traditional PP/PE, this bioplastic also possesses special characteristics of coffee grounds such as sterilization, natural dark brown color and light coffee aroma.

The natural ingredients in coffee bioplastics account for more than 60%, so the product is less dependent on fossil raw materials which make the price more reasonable.

2. Fully biodegradable

Coffee bio-composite meets the strictest biodegradation standards from prestigious organizations around the world such as DIN CERTCO, TUV AUSTRIA, USDA,…

3. Environmentally friendly

Coffee bioplastic, after being buried or burned, will decompose into biomass, water, CO2 or CH4, capable of helping the development and growth of plants, not decompose into microplastics, and create environmental pollution.

After that, the plants will continue to provide natural materials for the production of our bioplastic. Thus, the life cycle continues to rotate, forming an optimal cyclic process, contributing to positive effects on the environment.

4. Safety for health

Passing a series of rigorous tests according to European and American standards, the coffee bioplastics themselves achieved REACH/Rohs certification, Food Contact Materials (FCMs) ensure absolute safety when the product is in contact directly with food, even when used with hot food and drinks (100 degrees Celsius)

Coffee bio-composite is committed to being non-infectious and containing no harmful ingredients (BPA) for human health.

Applications of coffee bioplastic

Our bioplastic is completely capable of applying film blowing, extrusion and injection molding technology to produce finished products such as cups, food containers, knives, spoons, forks, straws,…

Purchasing Policy

Please visit Biopolymer Website, then click “Contact Us” and leave the necessary information. Our Biopolymer team will advise about sizes and quotes as soon as possible.